Oil & Gas

Refinery

Petrochemical

Chemical

Pharmaceutical

Power

Steel plant

Pulp & paper

We offer excellent solutions for different processes and all types of fluid: on-off valves, control valves, valves in emergency systems, quick-acting shut-off and safety valves, designed for installation in steel plants, thermoelectric power plants, turbines and gas compression plants.

Our control and ON-OFF valves can be found in: refineries, chemical and petrochemical plants, pulp and paper plants, pharmaceutical industries, gas recovery plants and new hydrogen technologies.

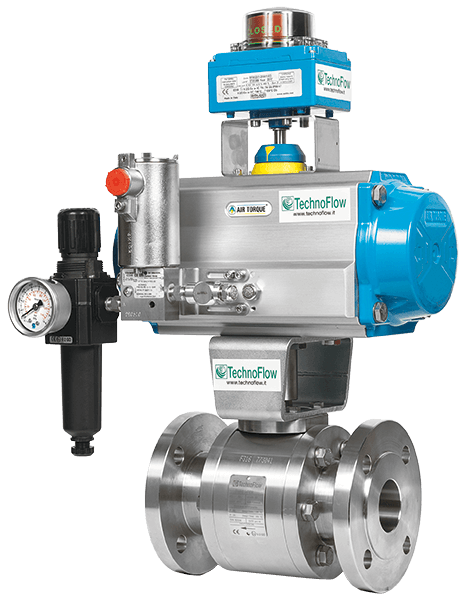

ON-OFF valves

Our range includes floating and trunnion ball valves, with soft and metal seated, with rating up to 4500 lbs and for temperatures above 500°C and butterfly valves with axial (centric) movement, double and triple eccentric, rating up to 2500 lbs / PN400 and temperatures above 1000°C. These constructions are manufactured up to very large diameters.

Emergency Shutdown Valves (ESV) are configured to customer specifications in line with the required parameters, such as strocking time and SIL certification.

Fugitive emission requirements (EN ISO 15848) as well as ATEX, Fire Safe and PED certifications cover the entire range.

The product range is completed by systems with double block and bleed ball valves (DBB), cryogenic valves and globe valves with bellows for toxic and lethal fluids.

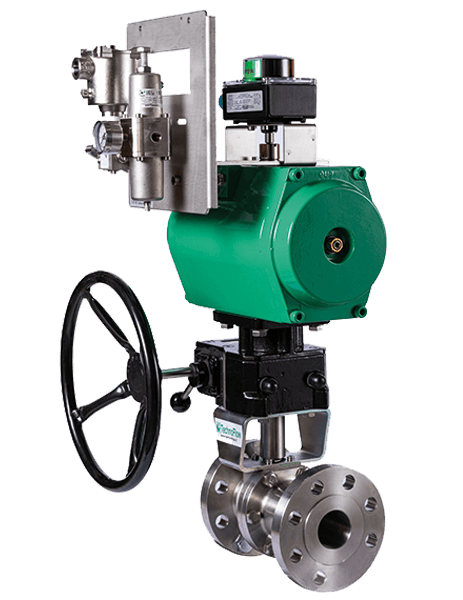

Control valves

Our range consists of globe, ball segment, ball and butterfly control valves, which allows us to offer suitable solutions for different types of service, with ratings up to 1500 lbs.

The different types of valves provide the option of choosing the best solution for the required performance.

It is part of our expertise to use specific calculation software to select the correct valve.

Valves with multistage and low noise trims, as well as butterfly and characterized ball valves, are engineered, sized and configured to specific process requirements.

Valves for special applications

Fully understanding our valves means that we can work with customers to find the correct construction, suitable for special applications.

Solutions for special applications can be made using our entire range of valves for both ON-OFF and control services.

The utmost importance is also given to the engineering and manufacture of electro-instrumental control panels.

Sampling valves and sampling systems

To meet production requirements for process analyses, we can offer a whole range of sampling valves and sampling systems. These configurations ensure frequent and safe sampling, production monitoring and certainty of product output.

Sampling valves and sampling systems have a modular configuration and are tailored to each individual installation.

Measuring instruments can be incorporated into the sampling systems for process analyses.

Considerable attention is paid to protective equipment for the operator and the environment during sampling.

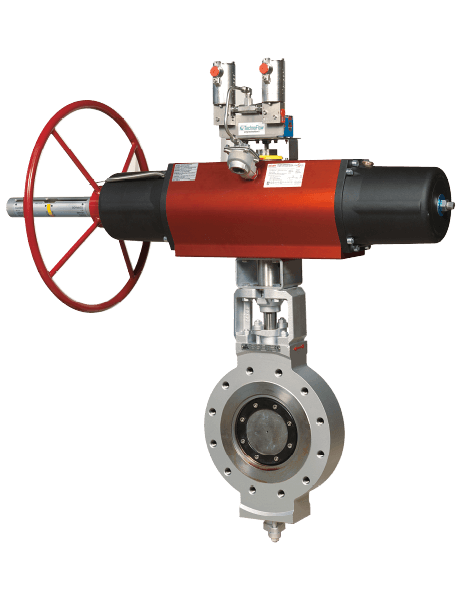

i-FGS valves

Our i-FGS valves have been developed and engineered for all those high temperature services that mark the operational limit for valves with soft seats.

Our patented lamellar graphite seats allow i-FGS valves to be installed on high temperature service fluids, gas and steam, offering reliability and high performance.

The construction of the valve with 3-piece body provides great flexibility in the various combinations of piping connections. Composite seats offer a low actuating torque compared to traditional metal seated valves, enabling an optimised actuator selection.

This design philosophy combines cost rationalisation and easy restoration of valve operation in the field, to the benefit of plant process operability.